Supply chain issues have been a day-to-day factor for the food industry since nearly the beginning of the pandemic. While there’s little question that a light has appeared at the end of the tunnel, there is less certainty about an actual return to normal – or what that normal is. It’s an uncertainty that only gets muddier with the reading of news stories, even those from generally reliable publications.

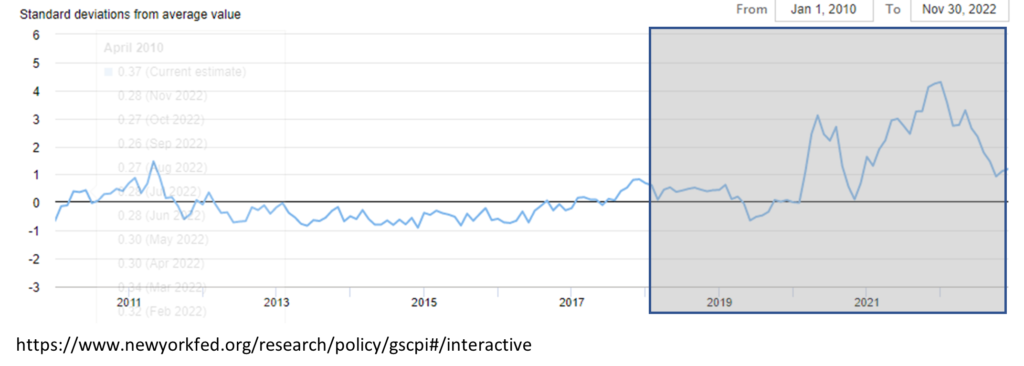

Take, for example, the recent contradicting headlines posted within days of each other: Supply Chains Upended by COVID Are Back to Normal (WSJ) and Don’t Expect A Return To Supply Chain Normalcy In 2023 (Forbes). Causing further head-scratching is the citation by both of the NY Federal Reserve Global Supply Chain Pressure Index to support their sides. While Forbes included a clip from the index extending back to 2010 (below) to show that pressure is greater today than during the past decade, WSJ provided a clip that went back to 2018 (boxed in gray) to show its trend toward prepandemic levels of pressure. In neither case, however, do today’s levels near the norm, whether that would be considered to be 0 pressure or the somewhat elevated pressures of just before the pandemic.

Given the diverging perspectives, perhaps the best descriptor of the current status is that from Fast Company which not only includes a caveat, but also plays both sides of the fence, stating that while “most supply chains have ironed themselves out (to a degree) … supply chains around the world are still, by and large, shaking off the effects of COVID-19 and the disorder it has unleashed.”

Let’s delve a bit deeper into each:

- The WSJ article notes that improved shipping rates, delivery capacity and retailer inventory have soothed the supply chain woes of the pandemic with goods moving around the world again and reaching companies and consumers, despite some production snarls. There are no longer cargo ship backlogs and ocean shipping rates are below prepandemic levels. In the U.S., retailers have ample, or even excess, inventory and package delivery trucks have spare capacity.

- Forbes concedes that the primary issues are no longer logistics, but logistics are only one of the factors that impact the supply chain. “The focus is now juggling the issues with recovery from record inflation, radical shifts in demand, slowing growth, bloated warehouses with wrong inventories, and supply shortages.” Add to that the potential risk from new COVID variants and China’s lifting of its zero-lockdown policy, and Forbes perspective is that “COVID impact on supply is far from over.” The article also considers supply chain pressures from factors not in the index, including inflation, demand downturn, supply shortages, and weather disruption.

- While Fast Company sees the world as still shaking off the disorders caused by COVID, it also cites experts who say things will improve, but don’t expect a full return to normal. This is in part due to the contrasting shortages and overstocks of various goods that will continue to cause consumers to face steep discounts for some products and high markups on others, “all because the world’s supply chains are still ironing themselves out.” And many of the shortages and related pricing have significant impact on the food industry, including those of diesel fuel, food/ingredients, fertilizer, labor, and even medications exacerbating absenteeism.

Taking all this together, TAG’s perspective aligns most closely with the conclusion stated by Forbes: while there is some relief to be derived from moving forward from the worst of the supply chain issues of 2022, there will be new challenges in 2023. But rather than ending with “Best of luck in your journey,” as Forbes does, we’d like to provide assistance to help you through the year.

Be prepared for ongoing supplier issues. Some of your most reliable and long-term suppliers are likely struggling with labor shortages and their own supply chain disruptions. Continuing to focus on supply chain control is key and our top recommendation is to ensure you are informed and prepared. While staying attuned to trusted news sources (note the plural!) and keeping an eye on regulatory happenings, be sure to subscribe to TAG’s weekly newsletter and YouTube channel for the latest updates and industry perspectives. Second is to be proactive. Don’t wait until the 11th hour to understand and comply with new regulations; don’t procrastinate on improvements until FDA is at your doorstep; and don’t hesitate to ask for help. Make TAG a part of your team to help mitigate operational, regulatory, and reputational risk while ensuring your food safety and public health practices are the best they can be. Contact us today!